Ancona, Italy, 21-23 June 2023

PRESENTATION

The International Conference on Vibration Measurements by Laser Techniques was first held in October 1994 and since its very first edition it has met large consensus among the International Research Community.

Download the Call for Papers here.

Click here for the list of Measurement Techniques and Application Areas given as guidance.

Extended abstracts on the topics of the conference must be sent to the Conference Secretariat together with the Pre- Registration Form.

Abstracts should include:

1. Title of paper;

2. Full names of all Authors (the name of the Presenting Author must be underlined);

3. Affiliation;

4. Text (about 500 words plus supporting figures).

Authors are requested to send their abstracts by e-mail to: aivela@univpm.it.

Notification of abstract acceptance and instructions for manuscript preparation will be provided by 29th April 2023.

PROCEEDINGS

The proceedings will be published in electronic format after the event by an internationally renowned Publishing House and indexed in the leading databases of scientific & engineering literature, including SCOPUS, ISI Web of Science, etc. Further details will be available in due course.

The official language of the Conference is English.

FINAL PROGRAMME (updated on 19th June)

Download the full Programme here

08.45 | REGISTRATION | |

09.15 | AULA MAGNA | |

09.30 | AULA MAGNA | |

10.20 | AULA MAGNA | |

11.00 | COFFEE BREAK | |

11.20 | AULA MAGNA | AULA N |

13.00 | LUNCH | |

14.30 | AULA MAGNA | |

15.20 | AULA MAGNA | |

16.00 | COFFEE BREAK | |

16.20 | AULA MAGNA | |

18.00 | END of DAY 1 | |

20.00 | GALA DINNER at SEEPORT HOTEL | |

| ||

THURSDAY, 22nd June | ||

09.15 | AULA MAGNA | |

09.30 | AULA MAGNA | |

10.20 | AULA MAGNA | |

11.20 | COFFEE BREAK | |

11.40 | AULA MAGNA | AULA N |

13.20 | LUNCH | |

14.50 | AULA MAGNA | |

15.40 | AULA MAGNA | |

16.40 | COFFEE BREAK | |

17.00 | AULA MAGNA | |

17.30 | AULA MAGNA | |

18.30 | END of DAY 2 | |

19.30 | APERITIVO at GUASCO BISTROT | |

| ||

FRIDAY, 23rd June | ||

09.15 | AULA MAGNA | |

09.30 | AULA MAGNA | |

11.30 | COFFEE BREAK | |

11.50 | AULA MAGNA | |

12.50 | LUNCH | |

14.00 | FINAL GREETINGS & END of CONFERENCE | |

Invited Lectures & Tutorials will be delivered by leading personalities and instrumentation manufacturers in the field of vibration measurements by laser and non-contact techniques.

“Combining LDV with flying and moving platforms for flexible measurements on large structures: Joint research of TU Clausthal and the DLR“

by Prof. Christian Rembe, TU Clausthal, Germany

“The role of experimental dynamics in an era of Artificial Intelligence”

by Prof.Dario Di Maio, University of Twente, The Netherlands

He then worked as a post-Doc in the Rolls-Royce Composite Centre at Bristol University.

He was promoted to Assistant Professor of Dynamics at the Mechanical Engineering Department of the University of Bristol. He then moved from the UK to the Netherlands, where he is Assistant Professor of Dynamics at the University of Twente. His research interests include experimental dynamics, vibration measurements, vibration fatigue of composites and modal testing.

ABSTRACT

Optical methods have been one of the techniques for measuring mechanical properties whenever a test structure is not physically accessible by contact sensors, such as in an extremely hot environment. Our structural dynamics community have been using non-contact methods because of its full-field feature, which enables a much more detailed description of the dynamical deformations of structures. Large and dense response fields are so rich in information that the analysis and properties’ extraction were, and possibly are, never easy. Nevertheless, these measurement techniques are the core of experimental methods to underpin physical properties. Nowadays, AI provides fantastic tools for many data processing and analyses, which are becoming more and more accessible to non-experts. Our role as scientists and educators should be the by-pass between metrology and novel AI data analysis techniques.

“Novel Three-dimensional Continuous Scanning Laser Vibrometry for Structures with Arbitrarily Curved Surfaces and Novel Zero-contact Rotating Structure Vibration Measurement“

by Prof. Weidong Zhu, University of Maryland, Baltimore County, USA

ABSTRACT

This study proposes (1) a novel general-purpose three-dimensional (3D) continuously scanning laser Doppler vibrometer (CSLDV) system to measure 3D full-field vibration of a structure with a curved surface in a non-contact and fast way, and (2) a novel zero-contact image-based tracking continuously scanning laser Doppler vibrometer (CSLDV) system for measuring vibration of a rotating structure. Firstly, the proposed general-purpose 3D CSLDV system consists of three CSLDVs, a profile scanner, and an external controller. A 3D zig-zag scan path is proposed for scanning the curved surface of the structure based on results from the profile scanner, and scan angles of mirrors in CSLDVs are adjusted based on relations among their laser beams to focus three laser spots at one location, and direct them to continuously and synchronously scan the proposed 3D scan path. Modal parameters including natural frequencies, mode shapes, and operating deflection shapes of a turbine blade with a curved surface are identified by the general-purpose 3D CSLDV system and compared with those from a 3D scanning laser Doppler vibrometer (SLDV) system. The proposed 3D CSLDV system have the same accuracy as that of the commercial 3D SLDV system in modal parameter estimation. However, the 3D CSLDV system has much higher efficiency in obtaining 3D modal parameters of the blade than the 3D SLDV system. A novel mirror-assisted testing methodology for 3D CSLDV measurement that aims to extend the field of view of the general-purpose 3D CSLDV system to measure vibration of difficult-to-access areas of the structure without moving the system during the test, and stitch vibration of its different parts to obtain its panoramic modal parameters is also developed. Secondly, the proposed zero-contact image-based tracking CSLDV system consists of a single-point laser head, a scanner with a pair of orthogonal mirrors, a camera, and a controller. The camera takes images of the rotating structure. A novel edge detection method is proposed for processing images captured by the camera to determine positions and angular velocities of the rotating structure. One-dimensional (1D) and two-dimensional (2D) scan schemes are proposed for generating 1D and 2D scan paths on the rotating structure based on estimated positions of the rotating structure. The laser spot of the image-based tracking CSLDV system can be swept along generated scan paths by controlling rotation angles of mirrors of the scanner. A lifting method and an improved demodulation method are proposed to process measured responses of the rotating structure and estimate its modal parameters, such as damped natural frequencies, undamped mode shapes, and modal damping ratios. The image-based tracking CSLDV system can estimate modal parameters of a rotating fan blade with constant speeds or non-constant speeds.

“High-speed camera-based structural identification beyond 1/100.000th of a pixel”

by Professor Janko Slavič, University of Ljubljana

Prof. Slavič is a recipient of the Fulbright scholarship (University of Texas at Austin 2005-2006) and is a co-author of 82 scientific articles, 56 of which are in category Q1.

His works have been cited over ten thousand times. As a mentor or co-mentor, he has supervised 16 completed doctoral theses. In the last 10 years, his research has made significant contributions to the development of science in four scientific areas: vibration fatigue, experimental modal analysis based on high-speed camera recordings, 3D printing of sensors, and research based on open-source code.

ABSTRACT

Image-based measurement techniques have recently gained popularity and are increasingly used in various applications as a viable alternative to traditional measurement methods. Image-based techniques offer high spatial density of information, and with advancements in hardware, they can also provide a high frequency of image acquisition, such as 20k frames per second at megapixel resolution.

PRESENTATIONS

Presentations will be oral.

Presenting authors have 15 mins for their presentation, followed by 5 mins discussion.

Each session room will be supplied with an LCD projector and a PC with Power Point application.

Presenting authors can upload their presentations during the coffee break preceding their session or, for the opening morning sessions, before the beginning of the first presentation.

Authors who wish to do so can use their own computer hooked up to the projector.

MEETING with CHAIRMEN

Presenting authors are invited to meet the Chairman/ Chairmen of their session at the coffee break preceding their session or, for the first morning sessions, at the Chairmen meeting point just outside the main Conference room, Sala Ridotto, about 5 minutes prior to the beginning of the sessions.

BIOGRAPHICAL SKETCH

A short biographical sketch about the professional background of the Presenting Author is required as an introduction by the session Chairman.

CLICK HERE to download the bio sketch

IMPORTANT NOTICE

Authors and co-authors are expected to attend the conference or to have a designated representative available to preset their paper.

The failure of authors to appear causes disappointment to the attendees and creates problems with the

programme schedule.

Authors who can no longer participate in the Conference and give their presentation due to serious unexpected events are requested to advise the Secretariat as soon as possible.

08.45 | Registration |

09.15 | Welcome by Prof. E.P. Tomasini, the President of AIVELA |

09.30 | LECTURE |

10.20 | LECTURE |

11.00 | COFFEE BREAK |

11.30 | TUTORIAL |

13.00 | LUNCH |

14.00 | TUTORIAL |

15.30 | HANDS-ON SESSIONS |

18.00 | END of COURSE |

- their name and logo

- their company profile

- hyperlinks to the company’s website, products, videos, news and social media accounts

- leaflets and images

AIVELA 2023 EXHIBITORS

Click here to take a look at our Exhibitors’ latest products and services

The 15th Intl Conference on Vibration Measurements by Laser and Noncontact Techniques & Short Course will be held at the premises of the Faculty of Agricultural, Food and Environmental Sciences of Università Politecnica delle Marche.

The Faculty, which is a modern complex within the Monte Dago campus, stands right behind the Faculty of Engineering.

The full address of the Faculty is:

Via Brecce Bianche 10,

60131 Ancona

Tel (+39) 071.220.4935 (caretaker)

HOW TO REACH THE FACULTY

By Plane

From “Raffaello Sanzio” airport to the centre of Ancona:

– take the Aerobus Raffaello shuttle to Ancona.

The bus runs every day, it stops at Ancona Railway station and Piazza Cavour (town centre) and the journey takes about 30 mins. Tickets can be purchased onboard. The price is € 5,50.

The times change according to the flights’ timetable.

– take the train from Castelferretti to Ancona railway station and then #1/4 bus to Tavernelle. Check https://www.trenitalia.com/ for times and fares.

– take a taxi (www.ctftaxi.it, www.taxifalconara.it)

– rent a car (AUTONOLEGGIO MAGELLANO +39 071 9157086, AUTOVIA +39 071 9188038, AVIS +39 071 52222, EUROPCAR +39 071 9162240, HERTZ +39 071 2073798, LEASYS +39 071 9716163).

By Car

Take the A14 Bologna-Bari motorway, turn off at Ancona Sud, then follow the signs to Ancona and turn off at “Università”.

By Train

From Ancona Railway Station, take # 1/4 bus to the Faculty terminal in Tavernelle.

By Bus

– #46 bus leaving from Piazza Cavour (in the town centre). The bus runs every 15 mins and stops right in front of the main gates to the Monte Dago campus. The journey takes about 10 mins.

Once you reach the Monte Dago Campus, don’t enter the main gates to the campus but walk down the hill for about 40 m, walk pass a second gate (ingresso 2) and enter the third gate (ingresso 1) on your left. Take the first on the right and then the first on your left and go straight on until you reach the main building of the Faculty of Agricultural, Food and Environmental Sciences.

Download bus #46 timetable here.

– #1/4 bus from the town centre -Piazza IV Novembre (Passetto) to the Faculty terminal in Tavernelle. The bus stops at Piazza Cavour, Piazza Kennedy (near the Muse theatre) and Ancona Railway station.

Once you reach the terminal in Tavernelle, cross the road, turn left and take the first on the right. Walk up the hill for 120 m then take the pedestrian overpass. At the end of the overpass you will see a big gate on your right (ingresso 1), which is one of the gates to the campus. Enter the gate, take the first on the right and then the first on your left and go straight on until you reach the Faculty main building.

Downolad bus #1/4 timetable here.

Bus tickets can be bought through the app mycicero (http://www.mycicero.eu/) or from newsagents. Some buses sell tickets onboard1

A limited number of rooms are available at special rates for Conference participants at the hotels below until 26th May.

Ancona is extremely busy in June, therefore early booking is strongly advised.

HOTEL | LOCATION | SINGLE ROOM | DOUBLE ROOM-USE SINGLE | DOUBLE ROOM |

|

town centre | |||||

Hotel Milano *** | near Piazza Cavour | € 60 | € 75 | € 90 |

|

Grand Hotel Palace **** | near The Muse theatre | € 124 | € 154 | ||

NH Ancona **** | overlooking the harbour | € 95 | € 110 | € 120 | |

SeePort Hotel **** | overlooking the harbour | Executive: € 175 | Executive: € 225 | Free car park | |

Grand Hotel Passetto **** | near Passetto | Classic- view on the internal courtyard: € 119 | |||

opposite Ancona railway station | |||||

Hotel Fortuna *** | € 72 | € 82 | € 94 | ||

Hotel Della Rosa *** | |||||

near Piazza Ugo Bassi | |||||

Ankon Hotel *** | € 55 | € 65 | € 80 | ||

near the venue (car needed) | |||||

V Hotel **** | 5 mins drive from the venue | € 90 | € 100.00 |

| Free car park |

9 mins drive from the venue | € 58 | € 90 | Free car park |

The rates above do not include the “city tax”: € 2 per person per night.

To take advantage of the special rates, participants are required to make their reservations through the Conference Secretariat by filling in the Hotel Reservation Form below and sending it to aivela@univpm.it

Click here to download the Hotel Reservation Form

FLATS | ||||

near The Muse theatre | One-room flat for 1 person: € 45 | Two-room flat for 2 people: € 70 |

The rates above do not include the “city tax”: € 0.50 per person per night.

To take advantage of the special rates, participants are required to make their reservations through the Conference Secretariat by filling in the Hotel Reservation Form below and sending it to aivela@univpm.it

Click here to download the Hotel Reservation Form

Ancona is situated in the centre of Italy, in the Marche Region, on a beautiful harbour facing the Adriatic Sea, 210 km northeast of Rome and 200 km southeast of Bologna.

It’s Greek name, Ankon, means elbow.

The town, in fact, stands on a promontory that has the shape of an elbow, offering spectacular sunrises and sunsets over the sea.

TRAVELLING TO ANCONA

Ancona can be easily reached

by plane: “Aeroporto Internazionale di Ancona” (10 Km from Ancona town centre)

by train: direct connections from Milan – Rome- Bologna

by car: Motorway A14 Bologna – Taranto: Ancona Nord and Ancona Sud exits.

ABOUT ANCONA

Vincisgrassi

A variant of the classic lasagna, it is a typical Sunday lunch dish.

Legend has it that in 1799 a chef from Ancona cooked this dish for General Windisch-Graetz, from which the name “Vincisgrassi” derives.The ingredients for this delicious recipe are: fresh egg pasta, meat sauce, parmesan cheese and béchamel.

Moscioli

This is without doubt the “historic” wine of the district.

Mentions of it date back to Pliny (AD 23/24 – 79).

It is mainly suitable for meat-based dishes, which bring out the austere flavour and moderate tannins.

If aged for at least two years, it becomes Rosso Conero Superiore, which is softer on the palate, with a strong fruity component.

Verdicchio dei Castelli di Jesi

Verdicchio dei Castelli di JesiMade from Verdicchio grape variety, Verdicchio dei Castelli di Jesi is a DOC wine produced in the provinces of Macerata and Ancona.

Thanks to the particular quality of the soil, the good exposure and the cool sea breezes, this wine offers a complex aromatic profile.

Structured, full-bodied, elegant, it has a straw-yellow colour with evident greenish reflections. Verdicchio is ideal for pasta dishes, risotto and fish-based dishes.

Moving uphill from the port, we reach the nearby Colle Guasco. Here we find the ruins of a Roman amphitheatre, an impressive construction of the Augustan period. Attached to it is what many believe to have been a “school for gladiators”, housed in a building with mosaics of the same period.

This is where some of the most important monuments of Ancona can be found, such as Palazzo del Governo, the Church of San Domenico and the statue of Pope Clement X.

It takes its name from Mount Conero, which forms the homonymous promontory overlooking the sea.

At the foot of Mount Conero there is a whole series of white pebble beaches, bays, sea caves and woods surrounded by unspoilt nature.

– P. Avitabile, University of Massachusetts Lowell, USA

– S. Heyns, University of Pretoria, South Africa

– D.J. Inman, University of Michigan, USA

– A. Lohrengel, Clausthal University of Technology, Germany

– M. Martarelli, Marche Polytechnic University, Italy

– F. Mendoza Santoyo, CIO A.C., Mexico

– C. Niezrecki, University of Massachusetts Lowell, USA

– C. Rembe, Clausthal University of Technology, Germany

– D.J. Rixen, Technische Universität München, Germany

– J. Rohrbaugh, Washington University in Saint Louis, USA

– S.J. Rothberg, Manchester Metropolitan University, UK

– J.F. Vignola, The Catholic Univ. of America, USA

– W. Zhu, University of Maryland, USA

– W. Decraemer, University of Antwerp, Belgium

PARTICIPATION FEES

SHORT COURSE, 20 JUNE 2023 | ||

FEES | BEFORE 22nd MAY | FROM 23rd MAY |

REGULAR | € 380.00 | € 430.00 |

STUDENT | € 300.00 | € 350.00 |

CONFERENCE, 21 – 23 JUNE 2023 | ||

FEES | BEFORE 22nd MAY | FROM 23rd MAY |

REGULAR | € 550.00 | € 600.00 |

STUDENT | € 400.00 | € 450.00 |

| EXTRA PAPER | € 80 | € 80 |

CONFERENCE and SHORT COURSE, 20 – 23 JUNE 2023 | ||

FEES | BEFORE 22nd MAY | FROM 23rd MAY |

REGULAR | € 750.00 | € 830.00 |

STUDENT | € 600.00 | € 680.00 |

EXTRA PAPER | € 80 | € 80 |

Fees for the Conference include membership to AIVELA, publication of 1 paper, proceedings, coffee breaks and lunches, the gala dinner, visit to the Exhibition on 21-23 June.

Payment must be made by bank transfer to the credit of:

A.I.VE.LA.

MEET OUR SUPPORTERS & EXHIBITORS

general: info@motion-scope.com

sales: sales@motion-scope.com

support: support@motion-scope.com

web: https://www.motion-scope.com/

Tracking showreel

Leading camera-based motion measurement systems for displacement measurements, motion magnification, vibrations and modal analysis, acoustics, full-filed responses, Schlieren and more.

Measure thousands of points simultaneously with sub-micron accuracy!

MotionScope – Visualizing the invisible

Recent times have seen major advances in digital cameras, imaging techniques and visual analysis. Gone are the days of VGA resolution! Cameras now record HD and even 4k. Frame rates above 100 fps are not uncommon in modern consumer devices.

Motion Scope is a modern venture set at developing and implementing new, industry-leading and innovative technologies in the field of computer vision and imaging into easy to understand and intuitive products.

The company evolved from doctoral research on measuring structural vibrations with high-speed cameras. Structures ranging meters in size will exhibit vibrations ranging in microns, but can still be measured with cameras. The technology has proven to be more than prospective and warrant real-world use. This, coupled with mechanical and electrical engineering skill-set and years of high-speed imaging experiences brings us to Motion Scope.

We push the boundaries of what can be visually observed, by: peering into microscopic scales, warping time with high-speed imaging and measuring or visualizing minute motion far bellow the pixel scale with our tracking and motion magnification software.

The company is based in Slovenia (EU) and does business internationally. Our customers are predominately businesses and research institutions.

LASER VIBROMETERS

The measurable vibrations range from few tens of pm, to tens of mm, for frequencies from DC up to 100kHz, or 10MHz (with the ultrasound extended bandwidth option).

Julight Laser Vibrometer are capable of measuring directly onto any type of diffusive surface, without the need to use retroreflective painting or stickers, up to several meters distance. Working distance goes from 100mm to 5m for standard versions based on laser safety class 1 infra-red measuring laser, and up to 30m with long-distance option and laser safety class 3B.

LASER TRIANGULATION SENSORS

LASER VALVE MOTION SYSTEM

The basic version features one or more zero-delay laser triangulation sensors, which supply real-time displacement of the valves with high resolution, in the form of displacement, velocity and acceleration signal outputs. The zero-delay feature greatly help testers in the acquisition/interpretation of the valve lift, without the need to continuously synchronize the delay with respect to the camshaft/crankshaft encoder for varying rotation regimes.

An optional Laser Doppler Vibrometer based on SMI technology can be added, to allow automatic and real-time subtraction of the unwanted (but always present in practical experiments) vibrations of the engine head. The VSM system can be controlled by a PC using a dedicated software that communicates via Ethernet.

Optomet GmbH

Pfungstädter Str. 92,

64297 Darmstadt

Germany

Tel: +49 6151 38432-0

Fax: +49 6151 3688460

Email: sales@optomet.de

web: https://www.optomet.com/

Optomet is laser vibrometry for

non-contact vibration measurement

Combining state-of-the-art technology and sophisticated design in the development and manufacturing of laser Doppler vibrometers is our mission.

The results are high-precision, user-friendly measurement devices with world class performance.

Using latest generation FPGA-based signal processing and high-sensitivity SWIR laser measurement technology, Optomet defines a new standard for high performance laser Doppler vibrometers.

Optomet systems excel by a consistently digital workflow and can also be seamlessly integrated into existing analog data acquisition environments.

Optomet’s vibrometers allow customers to make the most accurate and efficient non-contact vibration measurements, all without surface treatment.

Vector-Micro-Optic

The Optomet Vector-Micro-Optic is an additional product for the Vector series and enables measurements on the smallest objects due to the extremely small laser spot (approx. 3um). It contains a 12 MP 4K camera so that precise placement of the laser spot on the test object is guaranteed. The Vector-Micro-Optic is ideal for use in electronics development and measurements on electronic components.

Characteristics

- Proven visible HeNe Laser source for precise multi-purpose vibration measurements

- Unmatched dynamic range enables vibration measurements from 0 to 25 MHz

- Extremely small laser spot size (approximately 3 um) for measurements on small objects

- 12 MP 4K camera included in Micro-Optics

- Precise placement of laser spot on test object

- Ideal for applications in electronics development and measurements on electronic components

- Optional positioning stage for precise alignment of test object and Micro-Optics system

- Compact all-in-one design

Nova Series:

Digital Free Beam SWIR Laser Vibrometer

The Nova series is a modern and digital free beam laser Doppler vibrometer (LDV), which works with a SWIR measuring laser (Short-Wavelength-InfraRed; SWIR). The Nova series is essential when every decibel is important for the signal level or exceptional dynamic range is required. Typical scenarios relate to structures that reflect visible light poorly, such as dark and rough surfaces or biological tissue. Even when measuring over long distances, for example in construction or on glowing surfaces such as turbine blades in the aerospace industry or in vehicle and plant construction, the signal strength is crucial.

Measurements on carbon composite panels or other non-cooperative materials can be carried out just as easily as measurements at distances of more than 200 m, without the need to treat the surface of the measurement object.

Fiber-Series:

Digital Fiber-coupled SWIR Laser Vibrometer

POLYTEC GmbH

Polytec-Platz 1-7

76337 Waronn

Germany

Tel: +49 7243 604-0

Fax: +49 7243 69944

Email: info@polytec.de

POLYTEC – Shaping the future since 1967

As an innovative high-tech company, Polytec provides cutting edge optical measurement solutions to researchers and engineers. Our commitment is to provide the most precise and reliable optical measurement systems and sensors available for non-contact measurement of vibration, length, speed, surface topography and for process analytics. Polytec instruments help to solve pressing application challenges both in R&D and manufacturing quality and process control, they help our customers to maintain and advance the leading position in their field.

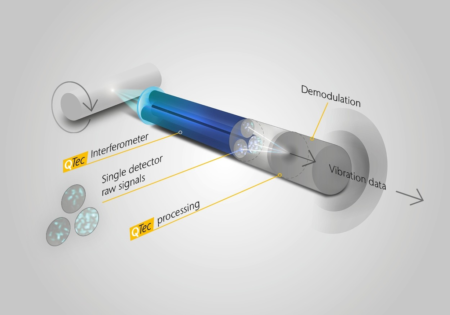

Polytec presents the latest achievements in Laser Doppler Vibrometry on it’s booth on the AIVELA conference. This includes single-point and scanning laser Vibrometers based on multi-path interferometers (QTec) featuring the best noise performance on all engineered and biomedical surfaces, the unique portable and autonomous Vibrometer VibroGo, featuring internal data recording and WiFi connection and the modular VibroFlex Vibrometer system.

Homepage: www.polytec.com

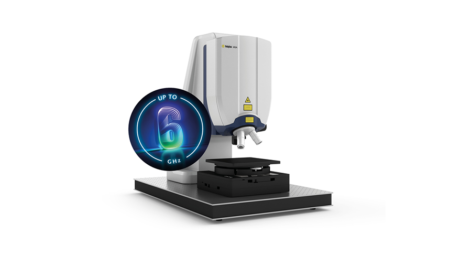

PSV QTec® – Reinventing Optical Vibration Mapping

With the new generation of the PSV QTec® Scanning Vibrometer, Polytec presents a completely new technology, which is nothing less than a revolution in the full-field optical measurement of vibration deflection shapes. With QTec®, Polytec has achieved a decisive breakthrough. Best signal-to-noise ratio on all surfaces makes measurements up to ten times faster and increases the usable resolution by up to 20 dB. This gain in data quality and test efficiency is especially crucial where optical vibration measurement can already show its advantages as a non-contact, non-invasive test method. The patented QTec® Scanning Laser Doppler Vibrometry makes the decisive difference in data quality and significance.

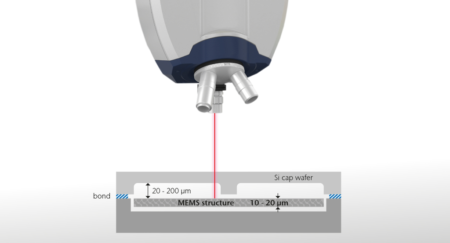

MSA-650 IRIS Micro System Analyzer – Microscope-based vibrometers

Optical characterization of dynamics on Si-capped MEMS

Visualization of dynamic response is key to testing and developing MEMS devices. This is indispensable for validating FE calculations and determining cross-talk effects. The innovative and patented MSA-650 IRIS Micro System Analyzer allows for measuring true MEMS dynamics by characterizing both in-plane and out-of-plane motions through silicon encapsulation without contact, without need for preparing nor decapping the device. The step of MEMS capping in fabrication processes may result in additional stress, which might alter the device performance. Therefore, a comprehensive characterization of the MEMS device in its final and encapsulated state is needed and indispensible.

VibroGo – Truly portable laser vibration measurement

VibroGo® is the truly portable, battery powered laser vibrometer for field studies and quick and easy condition monitoring of machines and facilities on the go.

This sensor measures the real vibration behavior, acoustics and dynamics of excited structures without contact and directly displays measurement data in the time and frequency domain. VibroGo® even allows on-board analysis in the field, while covering a wide frequency range of up to 320 kHz. Its outstanding resolution, with high linearity across the entire frequency range provides a handy precision analysis tool. Use VibroGo® for a better understanding of dynamics and acoustics in nature and technology – for research, product development and quality assurance.

VibroFlex – New flexibility in optical vibration measurement from nano to macro-sized structures

With VibroFlex, Polytec introduces the new flexibility in optical vibration measurement with a modular sensor solution that adapts to your needs: Add microscope optics for tiny structures or measure large, complex samples like machinery, motors etc. Discover acoustics and vibration phenomena in research and product development for a faster time-to-market or use it for reliable in-line inspections of your production parts with the focus on cost-efficiency.

NEW: QTec® Powerful on all surfaces

The VibroFlex QTec sensor head delivers the highest optical sensitivity, enabling high-fidelity measurements on all surfaces – even on dark, biological, rotating or moving objects. This eye-safe laser technology is perfect for challenging applications such as NDT, biomedical, long distance displacement measurements, quasi-static displacement measurement and shaker feedback control.

The patented and highly innovative technology QTec® makes vibration measurements faster, easier and more reliable than ever – for the most robust, unambiguous results.

Service and support

PolyXpert engineering services, system rentals and technical support

Polytec has at its disposal a global distribution network with branches in Europe, the USA and Asia and has dealers in all five continents. This global service network means you can be sure that your needs in the field of optical measuring systems and components as well as contactless vibration measurement technology will be met quickly and comprehensively – regardless of where you require our assistance. In short, wherever you are – we’re at your side.

Contact us now!

For any questions you may have, I am looking forward your call or email:

Dipl.-Phys. Thomas Karasinski

Sales International

Phone: +49 7243 604-1030

Mobile: +49 172 7275632

E-Mail: t.karasinski@polytec.de